Dual cylinder series

1、 The main structure and working principle of the machine tool:

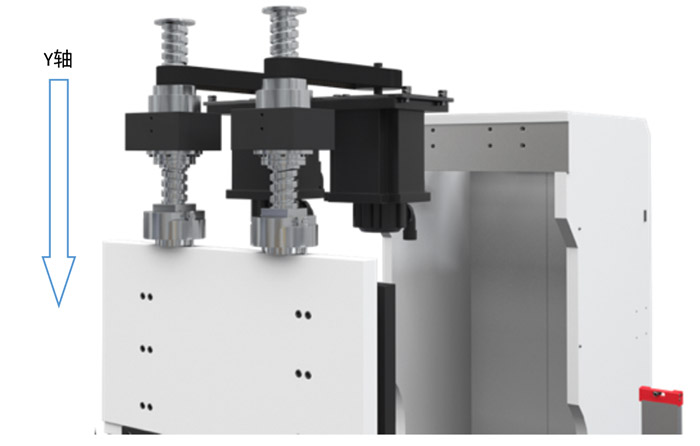

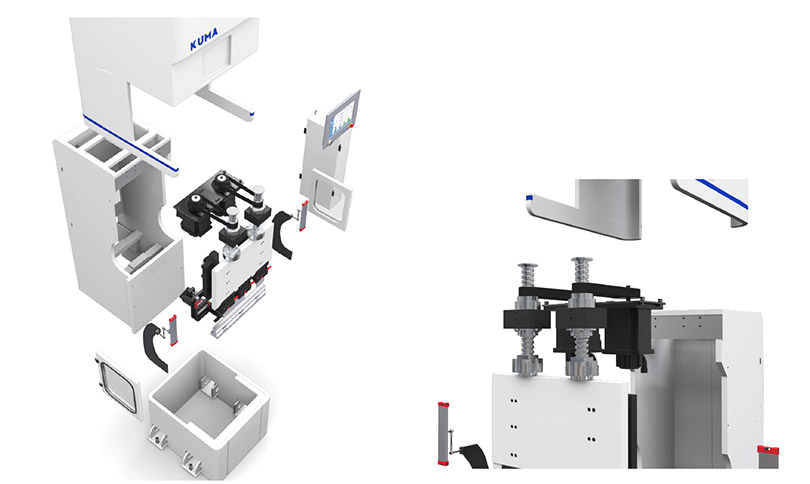

1. This machine tool mainly consists of a frame, a slider, a rear material blocking structure, a control system, and a mold

(1) Rack: Adopting an all steel welded structure with sufficient strength and rigidity, and simulating real load conditions through finite element analysis to achieve the required load conditions. After welding, annealing treatment is used to eliminate residual stresses in the frame welding.

(2) Sliding block: This machine tool adopts an eccentric axis guided sliding block structure, which has a simple overall structure and is convenient for debugging and maintenance.

(3) Control system: Adopting NCmax CNC bending system, this system is independently developed, with flexible and simple operation, which can be operated without the need for skilled operators. The program is simple and fast, and processing can be carried out without the need to input mold data in advance. The modification and execution of data are on the same screen, saving time and simplifying operations. Each axis uses relative position to record the origin, eliminating the problem of disappearance and resetting of the origin.

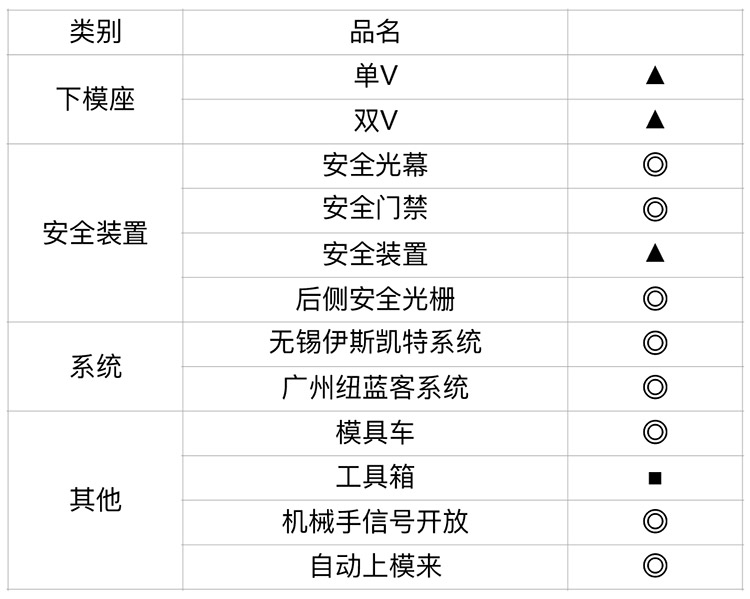

(4) Mold: This component consists of an upper mold component and a lower mold component. The upper mold is installed on the slider and fixed by a clamp plate. The lower mold can be in various forms such as single V, double V, and multiple V. The mold can be segmented or customized according to user requirements.

1.2 Working principle

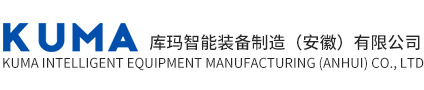

Machine tools are driven directly by servo motors to achieve high-speed rise and fall, stable repetitive accuracy, and efficient production.

Equipment features:

● Stable and durable:All adopt imported servo motors to ensure the accuracy and stability of the machinery, and they are durable.

● High precision and long lifespan:The screw guide rails are all imported C5 grade products with high accuracy, excellent performance, long service life, and the minimum Y-axis movement setting unit:0.005mm。

1.3 Saving

energy saving:The difference in electricity consumption between fully electric servo bending machines and electro-hydraulic servo bending machines is similar to the difference between variable frequency air conditioning and ordinary air conditioning. The fully electric servo bending machine automatically outputs appropriate power and energy according to the working conditions, and consumes less than 0.5kW of electricity when idle, making it more energy-efficient.

Green and environmentally friendly:No need to use or replace hydraulic oil, ending the pollution of waste hydraulic oil to the environment.

2、 Main parameters of the bending machine:

2.1 Overall Architecture and Main Components of Machine Tool

The pictures are for reference only, subject to the actual machine model and configuration

Main technical parameters of machine tools (dual cylinder series)

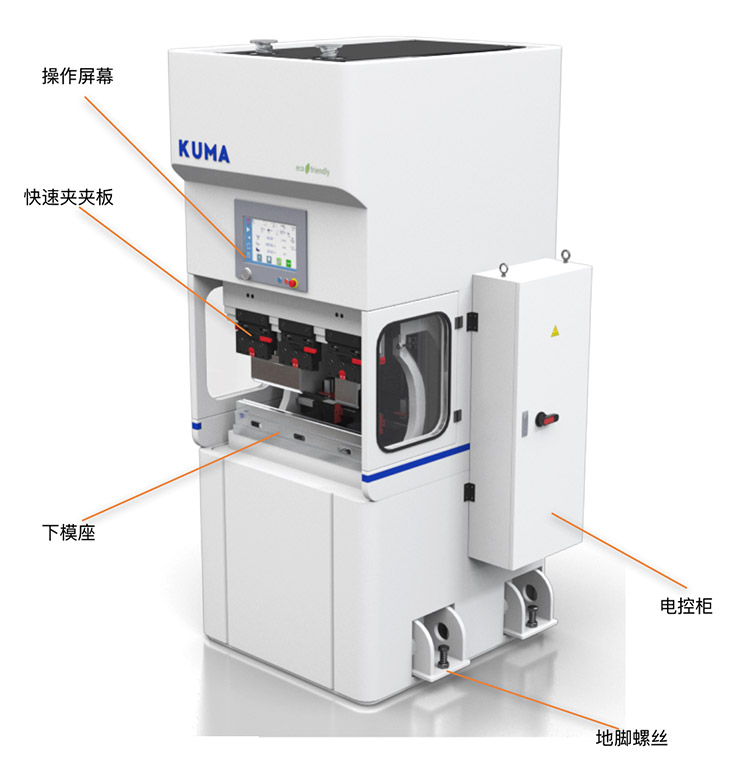

2.2 Machine Tool Dimensional Drawing (mm)

3、 Product appearance structure:

1. Kuma Intelligent Equipment Machine Tool (Anhui) Co., Ltd. independently designs and uses finite element analysis method to ensure the strength, rigidity, and safety of the machine.

2. Beautiful appearance, exquisite workmanship, and pursuit of details, whether it is mechanical processing, welding, component assembly, painting, labeling, etc., all strive for perfection.

3. Adopting high-quality steel plate welding structure, tempering to eliminate stress, the frame is thick, rigid, and has strong shock absorption.

4. The structural components are rust removed by sandblasting and sprayed with anti rust paint.

5. The column, upper working slider, and lower worktable of the machine tool are precision machined by a large CNC floor boring and milling machine, ensuring the parallelism, verticality, and parallelism of each installation surface.

6. Upward bending design, smooth operation, convenient operation, and safety.

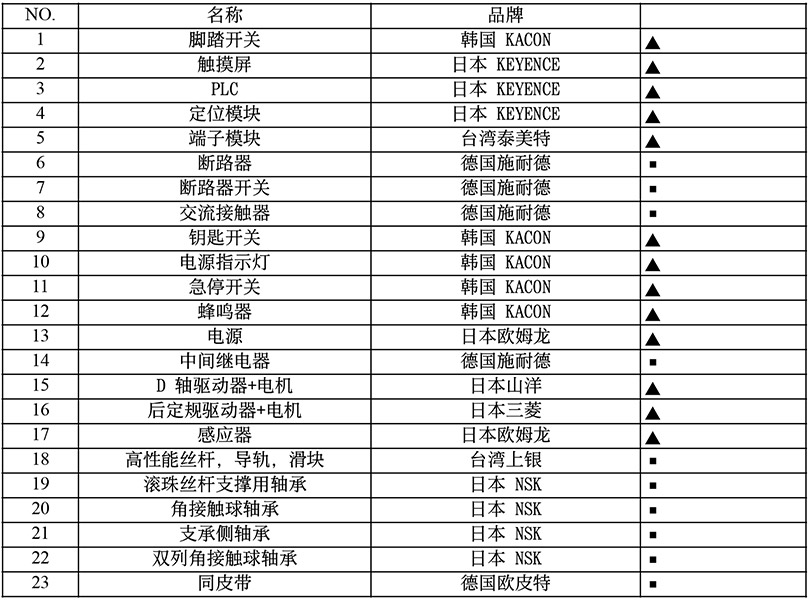

4、 Electrical control system:

1. The electrical components mainly adopt imported brands such as Schneider, which comply with international standards, are safe and reliable, have strong anti-interference ability, and the electrical control cabinet has heat dissipation function.

2. The foot switch controls functions such as bending processing and emergency stop.

3. The wiring of the electrical cabinet is reasonable and clear, making it easy to repair or troubleshoot.

4. The electrical cabinet body is customized by OEM from a leading professional control cabinet manufacturer in China.

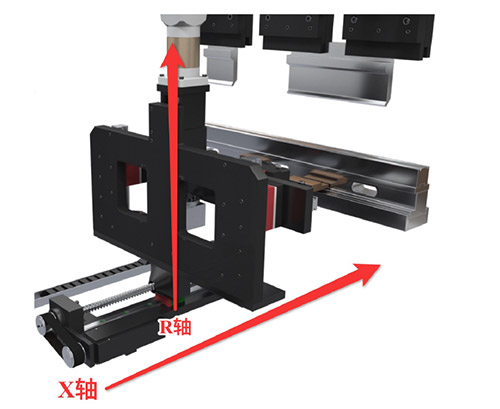

5、 Rear blocking material

The crossbeam is processed with high-quality carbon steel, and the overall structural design is simple, compact, and stable, resulting in fast speed and high accuracy.

The standard configuration for the rear stopper of this machine is X and Y axes, with 2 adjustable stopper fingers.

6、 Mold

Randomly equipped with standard molds, one set for upper mold and one set for lower mold (specific according to drawing requirements)

7、 List of selected brands for major outsourced parts. ▲:Optional / ■ :standard configuration / ◎:customized

8、 Product optional specifications ▲:Optional / ■ :standard configuration / ◎:customized

9、 Machine standard accessories (per machine)

1. 1 foot switch

2. 1 set of random tools

3. 1 set of product operation manual written in Chinese

Product real-life photos